With CSM Heartbeat and CSM Finecut systems you have the option of acoustically monitoring saw blades and reacting in a fraction of a second in case of a problem. The function of the saws is determined by many parameters. As soon as one of these factors deviates from its normal value, the saw blade starts to oscillate. This is recognized by CSM and the feed is optimized to a dimension that prevents the saw blades from vibrating.

CSM – circular saw monitoring

Listen to your saws!

Your cost saving

Higher productivity

better efficiency, higher throughput

Higher product quality

less waste, higher cutting accuracy

Lower saw blade wear

shorter set-up times, less sharpening work

Fewer complaints

higher customer satisfaction

Lower material consumption due to thinner saw blades

Reduced saw blade costs due to optimised maintenance cycles

the MAV indicates the real wear which determines the moment of maintenance

Return on investment (ROI) guaranteed in just a few months!

CSM Heartbeat – some of our satisfied customers

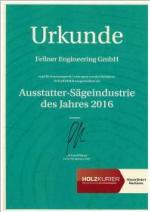

Our awards